The Tarmo project has been around since 2018 as the pet project of designer Kris Hellman but the Tarmo4 is the best version yet, at least until the Tarmo5 is released later this year!

<<Read on below or start by watching our “Should I build it?” review of the Tarmo4 on Youtube.>>

Files: https://www.thingiverse.com/thing:4178426

BOM: https://docs.google.com/spreadsheets/d/1L_gyqe0Z0M6EqGA_9Atzdi2MuHHSS75mls500SyTOlY/edit#gid=0

Instructions: https://docs.google.com/document/d/1hfrpDU1DQm6QKrioJsxxcMdq8ormYTlwAHaiswDuSHI/edit

Build Guide: https://www.reddit.com/r/EngineeringNS/comments/ic0wqk/build_process/

Video Build Guide: https://www.youtube.com/watch?v=A6_cZBMJYog&ab_channel=RCPrinter

Backgroud: The Tarmo4 3D printable RC project was designed by Kris Hellman, an engineer by trade and known online in the 3d printing world as "Engineering Nonsense". If you want to find out more about his projects the best place to do so is on Reddit at http://reddit.com/r/engineeringns. That forum is monitored by some of the friendliest, most helpful people on the internet and if you have any issues at all they’re be sure to help you out. You can also see what Kris is upto on Instagram here: https://www.instagram.com/engineeringns/

The Tarmo4 is the 4th model in a lineup of increasingly more refined rc cars designed by Hellman. If you check Thingiverse you can find files for the Tarmo4 which came out in April 2020 and the Tarmo 3 which came out around April 2019. The Tarmo3 and is the first version of the Tarmo that you can easily find online however if you check youtube you can find Kris’ videos on the Tarmo2 and the original Tarmo from 2018. The Tarmo4 is a completely redesigned model which is 20% larger, heavier, and uses none of the parts from the previous versions. As of summer 2021 Kris was still working on the next version of the Tarmo, the Tarmo5. He’s already got a working prototype that he’s happy with but it needs some more refining before it’ll be ready for release.

Printing: Pretty much every part of the vehicle is printed in PLA, including the gears, differentials and dogbones, except for the lower front suspension bracket and driveshafts which are printed in a flexible TPU. When printing the vehicle you should pay close attention to the "instructions" google doc the designer released with specifications as its very important to follow it closely in order to give yourself the best chance of having a reliable vehicle. When he says 8 walls, with a .25 layer height and 10% infill, use 8 walls with a .25 layer height and 10% infill. Follow the instructions to the letter or you’ll regret it later when your RC car is breaking all the time. I didn’t encounter any big issues with the printing of these parts which are mostly designed with 3D printing in mind. One thing I did find was that some of the screw holes are a bit loose so watch that as you may need to reprint a few things with a bit of over-extrusion to compensate.

General Design: In general the design quality of this car is pretty impressive and very sturdy. The chassis is quite thick and screwed together with m4 rod for rigidity. The build uses a mixture of m3 and larger m4 screws for strength. While the design is sturdy it is also quite heavy.

Suspension: The suspension uses 80mm shocks which give it a pretty good amount of bounce. Make sure you get some decent quality shocks which can lift a heavier vehicle. Originally I had tried some lower quality shocks but the suspension wasn't strong enough to lift the heavy vehicle. One of the suspension mods that I added to my build was higher shock towers and I did that because I thought the A-arms were being allowed to drop too low and putting too much stress on the dogbones and diff cups.

Drivetrain: Kris has designed the model to use a D3542 outrunner motor for a bit of increased torque over your regular 1/10 rc motor. He’s also engineered really cool TPU driveshafts which are brand new for the Tarmo4. They flex when you hit the gas and reduce the possibility of blowing parts up. Where I do have most of my issues with reliability with the Tarmo4 is in the rear differential and I think there’s just too much power on 3S for these 3d printed parts to handle. So far I've broken many:

- bell housings.

- diff input gears

- differential gears

- wheel axles.

The only part of the rear drivetrain I haven’t had issues with is the dogbones which I find to be super sturdy. The front differential is an open diff and uses an off-the-shelf Traxxas diff kit part number 5382x and it seems to work great. Kris’ instructions call for wire to hold the metal diff in place but most people are finding it better to use m2 screws and there’s a remix on thingiverse to accept the m2 screws that works way better.

Steering: The steering is pretty beefy and I haven’t broken it yet. Make sure you use a good metal gear servo with a metal horn. You can make your own steering link out of m3 rod and rod ends or Kris has also recently released a printable one if you’d like. The design uses 3d printed print-in-place ball joints in the steering which work great and I've had 0 issues with them. In general the turning radius is bit large and I do wish that was a bit better however the machine has a tonne of power so if you want to turn sharply you can just hit the gas and spin around at any time :)

Wheels: The car comes with adapters for any standard 12mm hex wheel which is really nice and gives you a tonne of options for wheels. Kris recommends wheels which have an outside diameter (OD) of 100mm or less. Originally, on my build I used tires that were slightly too big which added a lot of stress on my drivetrain parts. After switching to tires less than 100mm OD I found my build much more reliable.

Electronics: Most of us are gonna power this machine with a 2s or 3s lipo battery. 3s is a higher voltage and will be much faster but will break more often, especially if you get something with a c rating above 25. Kris recommends a 3s, 15c battery from Hobbyking. I started off using a 3s 50c battery which is probably too much discharge power and caused me to break parts more often. You can opt to install a gyro if you want to spend a few extra bucks which should help with stability of the model at high speeds as the gyro will talk to the servo and make instantaneous micro decisions to counteract ground forces on the vehicle to keep it going the direction you want. For a radio you can pretty much use anything you want. I'm a fan of my Flysky radios but Kris recommends cheap DumboRC ones which also have gyro compatibility if you’re looking for something less expensive.

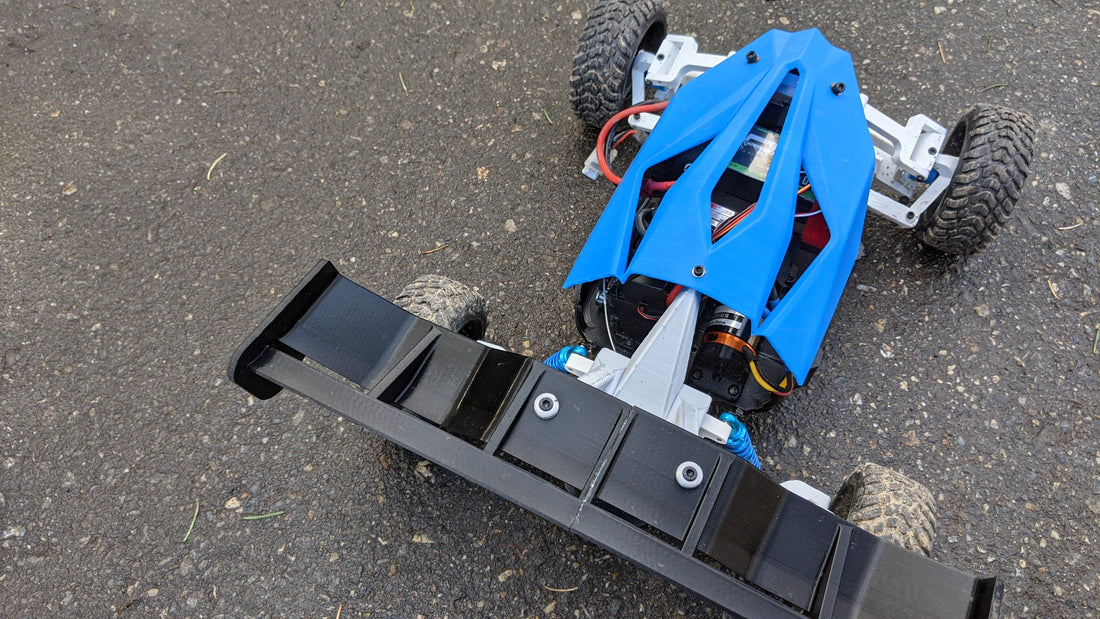

Body: For a body you have a few options but most commonly you’ll see the "skull" cover and giant wing which is what I installed on mine. The skull cover works well but its a bit of a pain to get on and off as it gets bolted down. IMO the wing is just too big and breaks too easily if/when you roll so you might want to look for another option although it does look really cool. One thing you definitely should install is some bumpers on the front and back. You can find a list of these mods here on github which was put together by one of those really nice Reddit users I was talking about earlier.

Photos: Here are some pictures of our build.